Release time: Tuesday July 30th, 2024

Alloy SteelType: 4140, 4142, 41L40, 8620, 52100, SKD11, SKD61

Machining Characteristics: alloy steel is suitable for products with requirements on strength

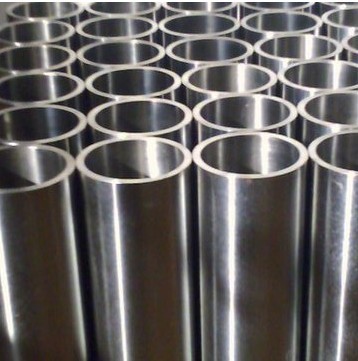

Stainless SteelType: SS303, SS304, SS316,SS316L SS416, SS430, SS440, 17-4PH etc.

Machining Characteristics: stainless steel is mainly used for products which can not rust and should be corrosion resistant. It is difficult to process stainless steel. The machining efficiency is low. The machining and customization of stainless steel parts are quite challenging. But our team knows well about the unique performance of 150 kinds of stainless steel. We can adjust our production process and improve the production efficiency at the max limits, ensuring the delivery time.

SteelType: 1008, 1018, 1045, 1137, 11L37, 11L41, 12L14, 12L15, 4130, 4140, 8620, Q235, Q345B, 20#, 45# etc.

Special steelType: Tungsten steel, ASP23, SKH51 etc.

Machining Characteristics: SKH51high speed steel is popular in most applications because of its superior well-balanced toughness and wear resistance which is two times that of high carbon steel. SKH51 high speed steel is suitable to be made to tools with high wear resistance and hardness because it can keep the hardness of 64 HRC under 600℃ without deformation.

Alloy TitaniumType: Ti6AI-40, Ti6AI-40 ELI

Machining Characteristics: compared with other materials, alloy titanium features high strength and weight. It also features good malleability, salt tolerance and water corrosion resistance. It is the ideal selection of many industries and applications.

AluminumType: AL6061, Al6063, AL6082, AL7075, AL2011, AL2024, AL6051

Machining Characteristics: among the materials to be machined, aluminum parts are the most economical. The CNC machining and milling time of aluminum parts are shorter than that of the other metals. Because of the protective layer on the surface after being exposed to the air, the strength, corrosion resistance anti-rust property of the product are improved. Besides, the aluminum parts feature chemical resistance, malleability and high strength. For these advantages,We focuses on being leader of CNC machining of aluminum parts.

BrassType: C35300, C36000, HPb63, HPb62, HPb61, HPb59, H59, H58, H68, H80, H90 etc.

Machining Characteristics: compared with machining of other materials, brass turning parts are durable. It is economical. Brass machining and turning parts feature high heat tolerance and corrosion resistance. The machining and turning of brass parts are easy.

CopperType: C11000, C14500, C17200, C17300, C17500, C12000, C36000 etc.

Machining Characteristics: copper is the known best electric conductor. Meanwhile, the cost is relatively low. Our team found that copper machining is a smooth and simple process. Copper also features high corrosion resistance so that the copper parts are widely welcome in electrical applications.

PlasticType: Acetal, Delrin, Nylon, Peekm PTPE, Teflon, PVC, ABS, PC, PE, POM, PP, PEI etc.

Machining Characteristics: plastic parts are widely used in daily life and industry. Our team knows well about unique features of high performance and standard practical plastics. We know well about the most suitable shaft speed and feeding speed of plastic machining. Meanwhile, we adopt the special high precision cutter for plastic machining.