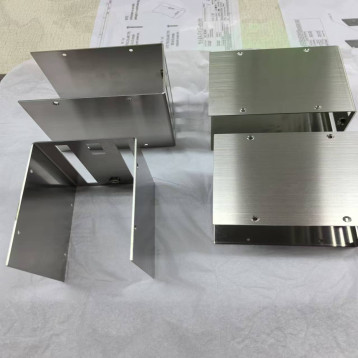

Metal stamping parts 3

Custom-made sheet metal parts are specialized components crafted from metal sheets, tailored to meet the unique specifications of a particular project or application. These parts are often designed and manufactured through precision processes such as cutting, bending, welding, punching, and stamping, which allow for high levels of customization in terms of shape, size, and material properties. Here is a breakdown of what custom-made sheet metal parts typically entail:

Overview

Custom sheet metal parts are essential in industries such as automotive, aerospace, construction, electronics, and manufacturing. They are used for everything from structural components to intricate enclosures, brackets, frames, and more. The main advantage of custom sheet metal fabrication is the ability to produce parts that perfectly fit the needs of a specific application, ensuring functionality, strength, and durability.

Materials Used

Common materials for custom sheet metal parts include:

- Stainless Steel: Known for its corrosion resistance and strength.

- Aluminum: Lightweight, corrosion-resistant, and easily formable.

- Steel: Offers strength and durability, ideal for structural parts.

- Brass and Copper: Used in electrical and plumbing applications.

- Galvanized Steel: Coated for enhanced corrosion resistance.

Fabrication Processes

- Laser Cutting: A precise method for cutting intricate shapes with high accuracy.

- Waterjet Cutting: Uses high-pressure water mixed with abrasive materials to cut through metal without heat distortion.

- Punching: A stamping method that creates holes or shapes in the sheet metal.

- Bending: Involves applying force to form the metal into a desired angle or curve.

- Welding: Joining metal parts through heat and/or pressure to create a solid bond.

- Stamping: A process that uses a die to shape or cut the metal into specific forms.

Applications

- Automotive Parts: Brackets, frames, body panels, exhaust systems.

- Aerospace Components: Structural supports, housing, and engine parts.

- Construction: Metal roofing, facades, ventilation systems, and structural framing.

- Electronics: Custom housings, panels, and enclosures for devices.

- Consumer Goods: Furniture, fixtures, and custom-designed decorative parts.

Advantages of Custom Sheet Metal Parts

- Precision and Fit: Tailored to exact specifications, ensuring that parts fit perfectly into their designated roles.

- Strength and Durability: Sheet metal parts are strong and can withstand harsh conditions, making them ideal for both indoor and outdoor applications.

- Cost-Effective for Prototypes and Small Batches: Custom sheet metal parts are ideal for creating prototypes or limited production runs without requiring large investments in tooling.

- Versatility: Can be used across a variety of industries and applications, from heavy machinery to delicate electronics.

Custom-made sheet metal parts offer a versatile, cost-effective solution for a wide range of industries. By leveraging advanced manufacturing techniques, companies can create precisely engineered parts that meet the highest standards of quality, performance, and durability. Whether it's for a complex aerospace component or a simple construction part, custom sheet metal fabrication provides the flexibility and precision needed to fulfill specific design requirements.